Spartan Engineer Chris Hause quit high school in his youth. It may be the only thing he’s ever quit since.

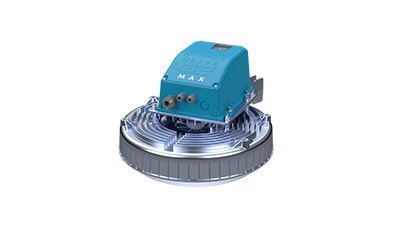

A 1997 mechanical engineering master’s graduate, Hause is one of the driving forces in ventilation and climate control equipment for the agriculture industry. He designed, engineered and patented a new motor for the agricultural market called Munters Drive.

Hause is the technology manager at Munters, a Lansing company that serves agriculture and horticulture dealers and growers. He has worked at Munters for almost 17 years.

The Munters Drive motor is the first PMAC (EC) motor specifically designed for agricultural applications. It helps farms save up to 40 percent of their electrical usage when ventilating a building. The company has sold nearly 40,000 Munters Drive units all over the world.

“Our products help keep the animals cool and healthy so they’re more productive, making more milk and eggs,” Hause explained. “We’re also helping the farm to be more energy efficient while doing so.”

Wouter Claassens, vice president FoodTech Americas, said nothing like Munters Drive had been built specifically for the demanding conditions of agriculture.

"It radically changed the marketplace and forever altered what modern-day engineering could do for today's farmers. These buildings often have hundreds of fans that require a significant amount of electricity, so eliminating any amount saves the farmer money and ultimately conserves valuable resources for the planet.

“Chris, along with other Michigan State alumni, played a significant role in advancing the industry. Engineers like Chris with their tenacity and spirit deserve our gratitude,” Claassens concluded.

Hause is an experienced research and development engineering manager. He specializes in electric motor design/manufacturing and the air moving/climate control industry. He has a half dozen patents on the products he developed through the years.

His future didn’t look very promising when he walked away from high school before graduating.

“I didn’t go to college until 1990, when I started at Lansing Community College. Kettering University followed that, and I noticed at my co-op that everyone had an advanced degree. I was an adult by then and went from Kettering to MSU. I was 37 by the time I graduated from MSU.

“In college I thought I had a goal but found out my goals had nothing to do with what I had really learned. What I got out of my education was problem solving skills. I learned how to effectively and systemically solve issues. Tactical, strategic. All of them.”

After graduating from MSU, Hause spent almost 10 years at Fasco DC Motors in Eaton Rapids.

“I learned my voice at Fasco,” Hause explained. “I learned how to speak up. I honed my problem solving and I worked on those skills. It’s a Tier 1 supplier for automotive, so that’s a pretty good learning ground.”

Then he joined Munters, where the leadership team recognized his potential and told him to “go at it.”

“I told Munters I could design, engineer and patent a new motor. It’s a project I had wanted to do for the five years prior. I patterned it after current washing machine technology – it’s motor design and how it was integrated into the product.”

Knowing that “the devil’s in the details,” Hause said, “we nailed our motor the first time and then repackaged it.”

Their innovation featured better balanced ventilation, that was more consistent and needed less maintenance because there are no belts to maintain. “We created a maintenance free product.”

Hause said the advantage of the design was it was specifically created for barns with animals.

“There’s a lot of moisture, dust and ammonia associated with housing animals. We improved the efficiencies and made it larger scale.”

Munters is currently in the final stages of designing a 74-inch fan for the dairy market.

“We had to create a new motor to handle that size of a fan. We’ll get it done.”

Hause has advice to offer MSU engineering students. Never quit, he said. Not in adversity or failure. Just don’t quit.

“And get your graduate degree,” he added. “Stick it out. I absolutely advocate for going straight from your bachelor’s to your master’s because there is no better feeling than watching a product launch. We hit home runs. I feel like I’m lucky.”

Hause has been married to his wife, Tina, for 42 years. They have 22-year-old twins, Savannah and Cameron.