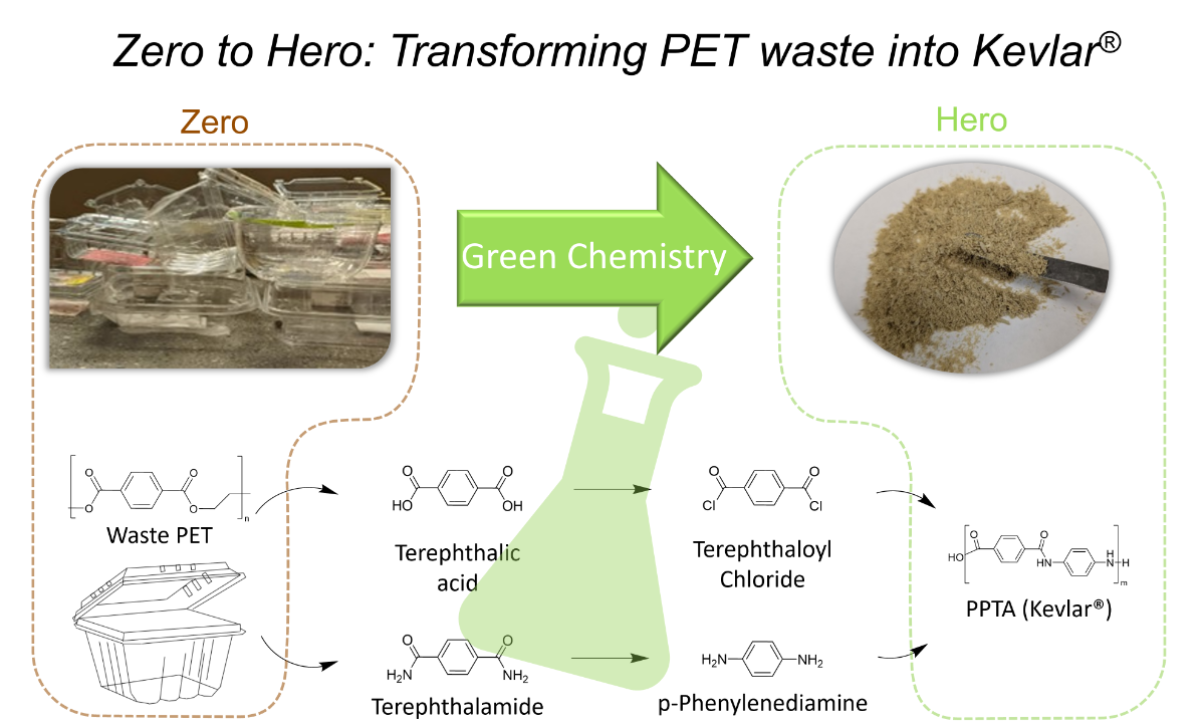

Researchers at Michigan State University are transforming low-value waste plastic – often destined for landfills – into high-performance materials like those used in protective applications such as bulletproof vests. The process is an example of a concept known as the circular economy, which aims to keep materials and products in circulation for as long as possible.

John Dorgan, professor in the Department of Chemical Engineering and Materials Science in the College of Engineering, is transforming polyethylene terephthalate (PET), a widely used single-use plastic packaging material into poly (p-phenyleneterephthalamide) (PPTA), a high-value commodity-scale polymer widely known by the tradename Kevlar®*.

Co-authoring the waste-eliminating research are graduate students Elanna Neppel and Richard-Joseph Peterson, and Research and Instruction Equipment Technologist Lars Peereboom, who work in his lab.

“We're involved in what we call chemical upcycling,” Dorgan said. “And so instead of recycling, where you're making the same thing, when you upcycle, you make something more valuable.”

During chemical upcycling, PPTA is synthesized using carbon that is entirely recovered from waste PET. This provides an economic means of reclaiming and reusing the waste, reducing dependence on nonrenewable resources and fostering greater material circularity in the plastics industry.

“You run a type of reverse chemical reaction on the polymeric material. So now we're going from the polymer back to the monomer,” Dorgan said. “Once we have made these monomers, they can be cleaned up and you can essentially make what the industry refers to as a virgin plastic material.”

What makes this research unique, he continued, is the increased value of the resulting material.

“If you can convert this waste plastic into something that's worth $50 a pound, there's an enormous economic driving force to motivate people to actually get the plastics out of the waste stream and to reuse them.

“We've been successful in converting the waste materials, which we call the zero materials, into Kevlar®*, which we call the hero materials because they're worn by members of the military and the police.”

The research is supported by the National Science Foundation program called Engineering the Elimination of End-of-Life Plastics, a program under the Emerging Frontiers and Multidisciplinary Activities.

“We've worked really hard to do something technically cool and socially important. Even more so, we’re involving young people and getting them excited, so that hopefully, they go on to apply their technical expertise to solving the complex issues shaping our future,” he added.

* Kevlar® is a registered trademark of affiliates of DuPont de Nemours, Inc.

Written by Judi Melena Smelser

MSU College of Engineering Media and Public Relations page