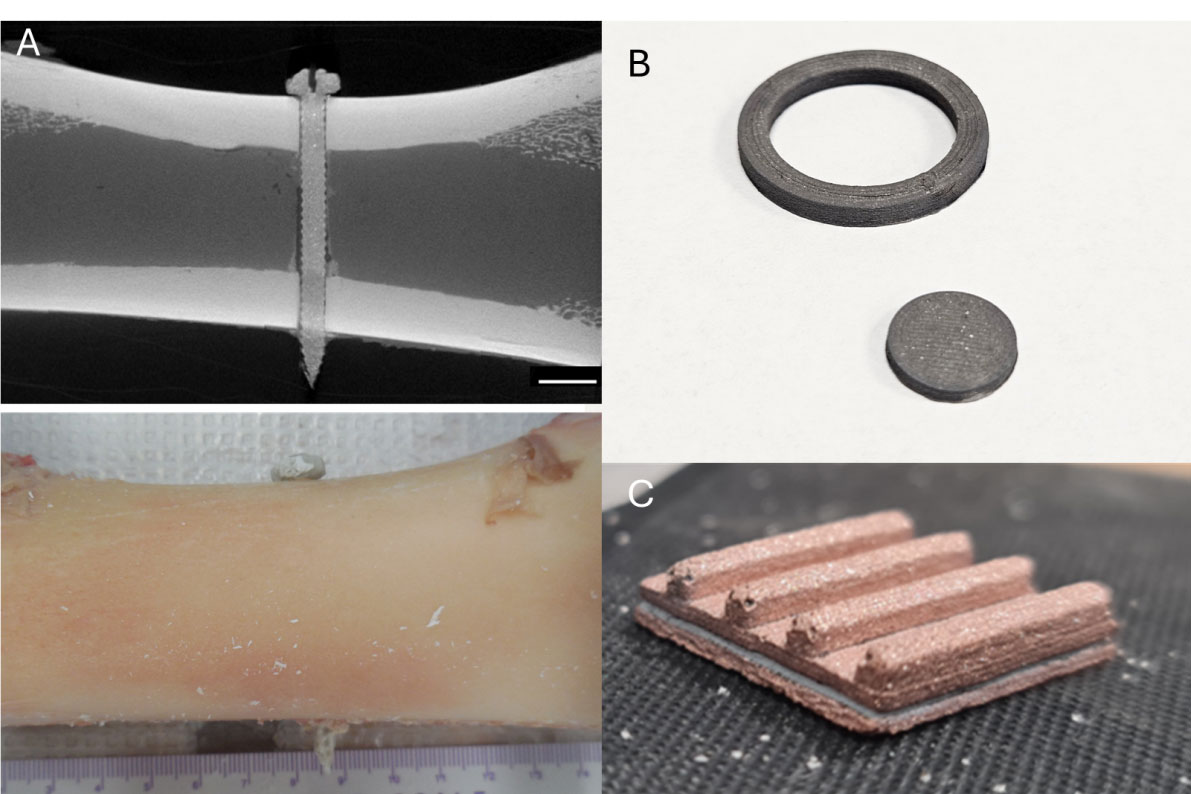

B. 3D printed and sintered electrical steel for magnetic studies

C. Co-3D printed and sintered copper and ceramic heat exchanger

Additive manufacturing (AM), also known as 3D printing, is transforming the manufacturing landscape and redefining how products are designed and produced. From universities incorporating design for AM into their curricula to prepare the next generation of engineers, to established manufacturers exploring print-on-demand and small-batch production models, this shift is reshaping how we think about fabrication. As this change takes hold, a fundamental understanding of how material properties evolve through additive processes is essential.

To address these needs, Fraunhofer USA Center Midwest (CMW) has partnered with Michigan State University (MSU). Since 2003, Fraunhofer USA CMW—a 501(c)(3) organization—has collaborated closely with MSU on applied research and development projects across CMW’s core competencies, supporting both government- and industry-sponsored initiatives. AM is a key area of focus, and together we have developed new analytical tools for applications ranging from biomedical implants and material characterization to metallic components for electric motors.

MSU College of Engineering Media and Public Relations page