Welcome to Chemical Engineering and Materials Science

Chemical Engineering and Materials Science offers two excellent degree programs to transform Spartans into innovative engineers with a foundation of mathematics, physics, chemistry, life sciences and engineering science. Students have access to outstanding laboratories for biochemical engineering, composite materials processing, and characterization of metals, ceramics, and polymers. New opportunities abound in microelectronics, biomaterials, environmentally friendly materials and nanotechnology.

Undergraduates experience the integration of engineering science and process design. Complementary areas of study include bioprocess engineering, biomedical engineering, environmental engineering, fuels and energy, materials, and food engineering. Graduates are prepared for life-long opportunities to participate in diverse sectors of the economy and to assume leadership roles throughout their professional careers.

428

Undergraduate Students

(Fall 2024)

91

Graduate Students

(Fall 2024)

96

Degrees Granted

(2023-2024)

$7.1M

Research Expenditure

(Fall 2023)

31

Tenure Faculty

(Fall 2023)

As Chairperson of the Department of Chemical Engineering and Materials Science (ChEMS) at Michigan State University, I am proud to welcome you to our department’s website. The ChEMS department is a community of scholars dedicated to innovation, excellence, and solving real-world problems.

As Chairperson of the Department of Chemical Engineering and Materials Science (ChEMS) at Michigan State University, I am proud to welcome you to our department’s website. The ChEMS department is a community of scholars dedicated to innovation, excellence, and solving real-world problems.

ChEMS offers two exciting programs: Chemical Engineering and Materials Science & Engineering. Chemical Engineering focuses on processes that produce and transform the chemicals needed by society. Spartan chemical engineers play critical roles in research, development, design, and sales in industries such as pharmaceuticals, energy, environmental science, food, biology, and medicine. Materials Science and Engineering combines physics, chemistry, and engineering to develop cutting-edge materials, like metals, ceramics, polymers, and composites. Innovations in materials are required by industries such as aerospace, biomedical technology, transportation, and microelectronics. Our department provides world-class educational programs in Bachelor’s, Master’s, and Doctoral degrees in both Chemical Engineering and Materials Science & Engineering.

Our department offers dynamic undergraduate and graduate programs that blend rigorous coursework in mathematics, physics, chemistry, and engineering science with laboratory experiences and cutting-edge research. Students benefit from access to outstanding facilities, including specialized laboratories for biochemical engineering, composite materials processing, and advanced characterization of metals, ceramics, and polymers. Our curriculum integrates engineering science with process design, preparing graduates for leadership roles across diverse industries. Many undergraduates participate in internships and co-op experiences, leading to competitive salaries after graduation.

For graduate students, we provide vibrant research opportunities in areas such as polymers, composites, metallurgy, biotechnology, biomaterials, microelectronics, and sustainable materials, with initiatives focused on sustainability, the circular economy, and advanced computational methods. Our faculty are recognized for their research excellence and commitment to student success.

To industrial partners, we offer collaborative opportunities through research projects, advisory boards, and access to a pipeline of talented graduates ready to drive innovation in your organizations. Together, we are shaping the future of chemical engineering and materials science—join us in this exciting journey.

At MSU, we provide life-changing academic experiences and cutting-edge research to solve global challenges. Please contact us if you need more information.

— Christina Chan, Chairperson

Bernard A. and Joan L. Paulson Endowed Scholarship

- Bernard A. (B.S. ChE, 1949) and Joan L. Paulson have endowed this scholarship to encourage scholastic achievement.

Carl M. Cooper Memorial Endowed Scholarship (A3026)

- Carl M. Cooper was an MSU Professor of Chemical Engineering for 32 years (1949-1981) and Professor Emeritus from 1981 until his death in 1993. Donations are welcomed for this fund to honor Professor Cooper. This fund became an endowment in 2005.

Chemical Engineering Faculty Distinguished Scholarship Fund (A30204)

- This endowment was started in 1998 by Chemical Engineering faculty contributors. The purpose of the fund is to "benefit worthy and capable students enrolled within the Department of Chemical Engineering in the College of Engineering at Michigan State University." This fund is being built to the endowment level.

Johansen Crosby Endowment

- The Johansen Crosby Endowment supports development of educational initiatives, such as the Johansen Crosby Lectureship and the Johansen Crosby Professorship. The Johansen Crosby endowment honors the parents of Professor Edwin Johansen Crosby. Professor Crosby received a bachelor of science degree in chemical engineering from Michigan State University in 1950 and continued his studies at the University of Wisconsin, completing the Ph.D. in 1955.

John Washington Donnell Memorial Endowment

- This memorial was established by Mary Louise Gephart Donnell to honor John Washington Donnell, with the principal purpose of supporting graduate students in chemical engineering.

James E. Raymond Endowed Scholarship

- James E. Raymond (B.S. ChE 1971) was a very dedicated student and proud alumni of MSU. He continually strove for the best, operating with the highest of ethics, in his more than 25 years as a chemical engineer at the Dow Chemical Company. Jim was a student and teacher at heart and always had goals to further his knowledge throughout his life. He truly led by example and has passed on that legacy to those who loved him.

Maurice G. and Sara V. Larian Endowed Scholarship

- This scholarship was established in memory of Dr. Maurice G. Larian, Professor of Chemical Engineering at MSU from the 1930s until 1971. It is for the benefit of outstanding chemical engineering students at MSU. The endowment is the result of the empathy between Dr. Larian and his students, and he would be pleased could he know that his concern for students has been extended and perpetuated. The endowment has grown over the years, through gifts from Mrs. Larian, friends, and some successful chemical engineering graduates, particularly Michael Dennos, ChE, '43.

M.S.U.-Chemical Engineering Alumni Scholarship Fund

- Each year the department awards scholarships made possible by alumni gifts designated for scholarships.

Lifeline Club Endowed Scholarship

- This award is intended to encourage chemical engineering students who have demonstrated the capacity to achieve educational and professional goals, the motivation to achieve these goals and the initiative to seek opportunities to further their progress. An important element of this scholarship is the recipients' "best effort" (non-binding) pledge to replenish the awarded funds over his or her lifetime and perhaps become a future mentor. The name, "Lifeline Club," is used to describe the concept and spirit of giving back for the benefit of the whole.

W.G. Shedd Materials Science Endowed Discretionary Fund

- After a career of 45 years in businesses intrinsic to materials engineering, Wilfred G. Shedd (B.S. ME, 1950) established this materials science endowment with the conviction that future advancements in manufacturing will be largely made through the development and intelligent selection of materials from which things are made.

William J. and Julia L. Hargreaves Fellowship in Composite Materials

- This fellowship endowed by William J. (B.S. ChE, 1946) and Julia L. Hargreaves encourages chemical engineering graduate students studying composite materials and polymers. Recipients have demonstrated the capacity to achieve educational and professional goals, the motivation to achieve these goals, and the initiative to seek opportunities to further their progress.

We have made every attempt to ensure the accuracy of this list, but despite our best intentions, human error does occasionally occur. If a mistake has been made, we apologize sincerely and encourage you to contact us at chems@egr.msu.edu or (517) 355-5135.

Thank you,

Professor Christina Chan, Chairperson

Department of Chemical Engineering and Materials Science

Related Contacts

College of Engineering Development Office

Engineering Building, 428 S. Shaw Lane, Room 3536

East Lansing, Michigan 48824-1226

Phone: (517) 355-8339

Fax: (517) 353-9405

Email: egrdevel@egr.msu.edu

Michigan State University Department of Chemical Engineering and Materials Science Alumni Advisory Board as of April 2025.

- Randy Beals

- Magna International

- Global Engineering Specialist

- Email: randy.beals@magna.com

- Isabel Boona

- Battelle Memorial Institute

- Computer Engineer III

- Email: isabelnboona@gmail.com

- Peter Votruba-Drzal

- PPG

- Vice President-elect Global Sustainability

- Email: pdrzal@ppg.com

- John Haworth

- Robert Bosch LLC

- Engineering Manager

- Email: John.haworth@us.bosch.com

- Frank Jere

- DTE Biomass

- Director -Technical Services

- Email: frank.jere@dteenergy.com

- Steve Klemm

- Cure Technologies

- President

- Email: srklemm@gmail.com

- Gaspare LoDuca

- Columbia University – Information Technology

- VP and CIO

- Email: Gaspare.loduca@gmail.com

- Linda Nartker

- DuPont

- Retired

- Email: lsnartke@att.net

- Matt Neurock

- University of Minnesota

- Shell Professor of Chemical Engineering and Materials Science

- Email: mneurock@gmail.com

- Avani Patel

- Dow Consumer Solutions

- Sr. Global R&D Director

- Email: ampatel@dow.com

- Adam Pilchak

- Pratt & Whitney

- Alloys Fellow

- Email: adam.pilchak@prattwhitney.com

- Craig Rogerson

- Hexion Inc.

- Retired

- Email: craig.rogerson704@yahoo.com

- Stacie Santhany

- Dow Chemical

- R&D Director, Dow Performance Silicones Process R&D

- Email: slsanthany@dow.com

- Abe Schuitman

- Corteva Agriscience

- Chemistry & Engineering Development Team Leader

- Email: abraham.schuitman@corteva.com

- Linsey Seitz

- Northwestern University

- Assistant Professor of Chemical Engineering

- Email: linsey.seitz@northwestern.edu

- Martin Toomajian

- Mag Plasma

- President

- Email: tmartin@magplasma.com

- Andy Wisniowiecki

- Albemarle Corporation

- Operations Engineer

- Email: wsnwck@gmail.com

- Kevin Zhou

- Novelis Global R&D, Joining & Additive Manufacturing Cluster, R&D Americas

- Senior Engineer

- Email: kevin.zhou1@novelis.com

Visit our college Alumni Awards page for information on awardees.

Chemical Engineering Teaching and Learning Facilities

The chemical engineering facilities consist of three undergraduate teaching laboratories, numerous research laboratories, several storerooms, and office space for faculty, staff, and graduate students. The laboratory space located in the Engineering Building (EB) is devoted to the Unit Operations Laboratory, ChE 316 (EB 1273 and 2265), the Polymer/Composites Laboratory, ChE 472 (EB 1254), and the Biochemical Engineering Laboratory, ChE 481 (EB 3262 and 3269).

The unit operations course, ChE 316, is a required course in the curriculum and thus must accommodate up to 140 students per year. The laboratory consists of four rooms on two floors, encompassing a total of approximately 2,500 ft2. The course may be taken in either the junior or senior year. Chemical engineering principles, including material and energy balances and momentum, heat and mass transfer, are investigated via hands-on experiments. In the lab, students work in groups of three on an experiment for five laboratory periods of three hours each; students conduct four or five experiments over the course of the semester.

The course includes an emphasis on the practice of engineering statistics by applying material taught in the lecture section of the course to analysis of data generated in laboratory experiments. Upon completion of the course, students are able to operate chemical engineering process equipment, collect, model, and analyze engineering data, work in teams, write clear, concise laboratory reports, and make oral presentations of their work. There are currently 15 active equipment stations in the unit operations laboratory:

- Stagewise distillation system with two 10-stage columns

- Stagewise distillation system with one eight-stage column

- Packed column absorption with two towers

- Double-effect evaporator

- Shell and tube heat exchanger

- Fluid flow/frictional loss apparatus

- Karr extraction column

- Spray dryer Batch reactor

- Permea gas membrane separator

- Stirred tank reactor system

- Laminar/Plug flow reactor system

- Mixing tank/unsteady state heat exchange apparatus

- Pneumatic conveying system

- Pumps apparatus (centrifugal and gear)

The Polymers and Composites Processing Laboratory, ChE 472, is an optional undergraduate course offered each fall semester to approximately 70 students. It may be taken in either the junior or senior year. This course is designed to teach students the relationships among processing variables, microstructure and mechanical performance of molded polymer products. Lecture topics are supplemented by laboratory experiments that demonstrate manufacturing processes for thermoset and thermoplastic matrix composites. Students also investigate mechanical, thermal and optical properties of composites along with transport properties, including the melt rheology and barrier properties of nanocomposites.

This lab and the bioprocessing lab (described below) serve as important links between our undergraduate program and research activities. The Polymers and Composites Processing Laboratory houses the following major pieces of equipment:

- Instrumented 75-ton Wabash press for compression molding

- Morgan press for prototype injection molding

- Single screw extruder with capillary rheometer assembly

- Differential scanning calorimeter

- Discovery HR-2 rheometer

- Thermomechanical analyzer

- Optical microscope with camera

- Mechanical test frame with environmental chamber

- Metricon prism coupler

The first three pieces of equipment serve to illustrate different types of molding or manufacturing methods. The next three are used to illustrate the characterization of thermal and rheological behavior of the materials used. The optical microscope is used to illustrate comparisons of microstructure obtained with different molding methods and processing conditions. The test frame is used to illustrate the effect of process induced microstructure on the mechanical performance of the product. The prism coupler enhances our ability to analyze the orientation state in transparent polymers and polymer nanocomposites through refractive index measurements. In addition, the students have access to MOCON units in the Composite Materials and Structures Center for measuring oxygen permeability of polymer films.

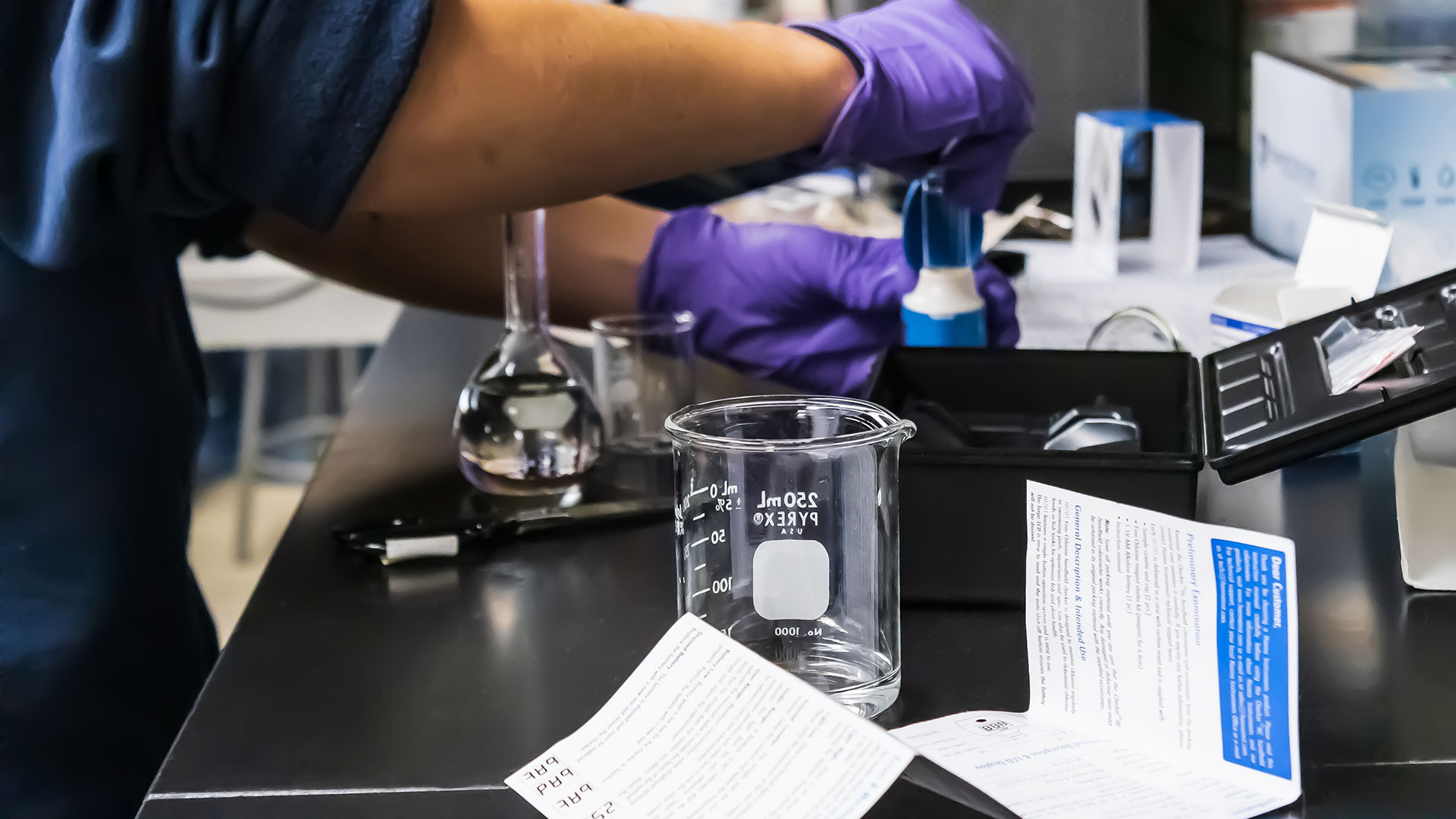

The Biochemical Engineering Laboratory, ChE 481, is an optional undergraduate course offered each fall semester to approximately 50 students. It may be taken in either the junior or senior year. The lecture component of this course emphasizes the application of traditional chemical engineering concepts to interdisciplinary technology areas that involve biological cells or their components. Lecture topics are supplemented by laboratory experiments that demonstrate applications of microbiology and biochemistry to biochemical engineering processes that are commonly used in the food, pharmaceutical, and biotechnology industries, but are not included in unit operations laboratory. Students investigate the kinetics and thermodynamics of biochemical reactors, and explore transport phenomena in biological systems. They also consider elements of bioreactor design and scale-up.

The Biochemical Engineering Teaching Laboratory (BETL) gives chemical engineering students hands-on experience with biochemical processes. The 2300 ft2 BETL was the result of capital-campaign investment by the MSU Engineering College and Chemical Engineering Department, as well as matching equipment donations from several companies and the State of Michigan vaccine production facility. The BETL allows students to gain hands-on practice with the following experimental techniques:

- Aseptic techniques for culture growth and maintenance

- Batch ethanol fermentation

- Enzyme kinetics

- Plasmid stability

- Diffusivity in immobilized cell biocatalysts

- Oxygen mass transfer

- Fermentation power transfer

- Membrane filtration

These experimental techniques reinforce student outcomes in the understanding, design, and analysis of biochemical processes, proficiency in the use of modern engineering tools, laboratory skills and data analysis, and the ability to work in teams on multidisciplinary problems.

Materials Science and Engineering Teaching and Learning Facilities

Students in the College of Engineering also utilize the beautiful, 21st-century classrooms and laboratory spaces in the STEM building.

Equipment

- Scanning Electron Microscope (JEOL) with SED, BSE, and EDX analysis

- Mechanical Testing Frame (Instron 5982; 100 kN load cell capacity, spindle-driven)

- 4 Inverted Optical Microscopes (Nikon Epiphot 200) with cameras

- 4 Stereomicroscopes (one with camera, Nikon SM 2645)

- 4 PCs for digital image capture and analysis

- 4 Vickers Micro-Hardness Testers (Clark)

- 4 Rockwell Macro-Hardness Testers (Buehler and Clark)

- Rolling Mill (Fenn; 4 inch rolls)

- Benchtop Shear (Jet SS8T)

- Abrasive Disc Cutter (Allied Powercut 10x)

- Charpy Impact Tester (Tinius Olsen)

- Single-Wheel Grinder (QATM Qpol 300M1)

- 4 Dual-Wheel Grinder/Polishers (Allied TwinPrep 5)

- 3 Ovens (Carbolite Gero, up to 300°C)

- 4 Furnaces (Thermo Scientific Lindberg blue M, up to 1200 °C)

Courses

- MSE 250 "Introduction to Materials Science and Engineering" is a Sophomore level course taken by approximately 500 students per year. It is the first undergraduate course for Materials Science majors, and is required of all Mechanical Engineering students. In addition, many students majoring in Applied Engineering Science, Chemical Engineering, Civil Engineering, Mechanics, Packaging, and Physics enroll in the course. Students learn how to measure physical and mechanical properties and explore the structure and properties of metals, ceramics, and polymers. They study basic crystallographic structures, phase diagrams, and thermomechanical treatments for strengthening.

- MSE 331

- MSE 381

- MSE 466

Equipment

- Tensile Frame

- Chemical analysis equipment

Courses

- MSE 331 "Materials Characterization Methods I" explores basic metallographic polishing/etching techniques, phase diagram construction, thermal analysis, and optical and scanning electron microscopy to characterize microstructure–property relationships. Students investigate the effects of processing on microstructure, properties, and fracture in metals, ceramics, and polymers. Specifically, differential scanning calorimetry (DSC) is used to examine the curing of thermosetting polymers and the formation of 2nd phase precipitates in metallic alloys, while a Dynamic Mechanical Analyzer (DMA) is used to investigate the recovery processes in cold-rolled metals, viscoelastic response of polymers, sintering process of powder ceramics. This class supports the learning goals of the concurrently taught lectures in MSE 320 "Mechanical Behavior of Materials."

- MSE 381 "Materials Characterization Methods II" extends the exploration begun in MSE 331 to include X-ray crystallography, and infrared spectroscopic analysis to characterize microstructure–property relationships and study processing effects (laboratory in 3545 EB). In the past couple of years, quantitative functional material characterization has begun, such as impedance spectroscopy, using portable equipment from faculty research labs, some of which has been transferred permanently to the teaching lab. Some of the laboratory experiences involving more sophisticated equipment not for general use by undergrads take place in the Composite Materials and Structures Center laboratory on the first floor of the EB in room 1130.

- MSE 466

Equipment

- Table-Top Testing Frame (Instron 4302; 10 kN capacity)

- X-ray Diffractometer (Bruker D2 Phaser)

- 2 Inverted Microscopes (Nikon Eclipse MA200 and MA100)

- Optical Microscope (Nikon Eclipse ME600)

- 2 Vickers Micro-Hardness Tester (Leco M-400-G1 and Clark CM-800AT)

- Hydraulic Carver Press

- Spot Welder (SEIWA SFW-412)

Courses

- MSE 331

- MSE 381

- MSE 466 is the MSE capstone course, which primarily uses the upper-class labs 3507 and 2004/2010 (STEM Facility), but also takes advantage of equipment in 3528, 3510, the College of Engineering Machine Shop, and various faculty research laboratories, as necessary. It fosters integration of knowledge of phase equilibrium and phase diagrams, microstructure, kinetics, mechanical properties, stress analysis, and processing methodologies to determine how design, fabrication, and service conditions lead to real-world failures. Legal, economic, and societal impacts of material failures are studied as well.

Equipment

- Diffractometer (Rigaku Smartlab)

- Diffractometer with Pole Figure Goniometer (Scintag XDS 2000)

- Laue X-ray CCD camera (Microphotonics Coolview FDI)

- Analysis Software (Orient Express and PDXL)

Courses

- MSE 481

Equipment

- Abrasive Grinder (Jade 700)

- 4 Dual-Wheel Polishers (3 Struers Labopol-25 and Leo Spectrum System 100)

- 2 Diamond Saws (Leco VC-50)

- Mounting Press (Struers Citopress-5)

- Abrasive Disc Cutter (Struers Labotom-3)

- 2 Manual Belt Grinders (Leco DS-20)

Courses

- MSE 331

- MSE 381

- MSE 466

Equipment

- Differential Scanning Calorimeter (Mettler Toledo DSC827e)

- Dynamic Mechanical Analyzer (Rheometric Scientific RSA III)

Courses

- MSE 331

- MSE 381

Composite Materials and Structures Center Laboratory

Equipment

- 2 Scanning Electron Microscope (Tescan Mira III and Zeiss Auriga)

- Scanning Electron Microscope at variable pressure (Zeiss EVO)

- Fourier-Transformed Infrared Spectroscopy

Courses

- MSE 381

- MSE 466